Europe continues to be the scene of great engineering works that redefine mobility on the continent. One of the most impressive is the Fehmarnbelt underwater tunnel, a colossal project that will link Germany and Denmark through the Fehmarn Strait, in the Baltic Sea. This tunnel will be the longest in the world, with a length of 18 kilometers, and will combine both roads and railways, which promises to transform travel between the two countries.

Environmental organizations have tried to stop the project due to its impact on protected reefs in the Baltic Sea. Construction requires dredging the seabed, which can negatively affect ecosystems. Additionally, with the construction of the bridge there have been delays due to disagreements over financing between Germany and Denmark.

(You can read: Colombia has the longest tunnel in Latin America)

Construction of the underwater tunnel in Europe

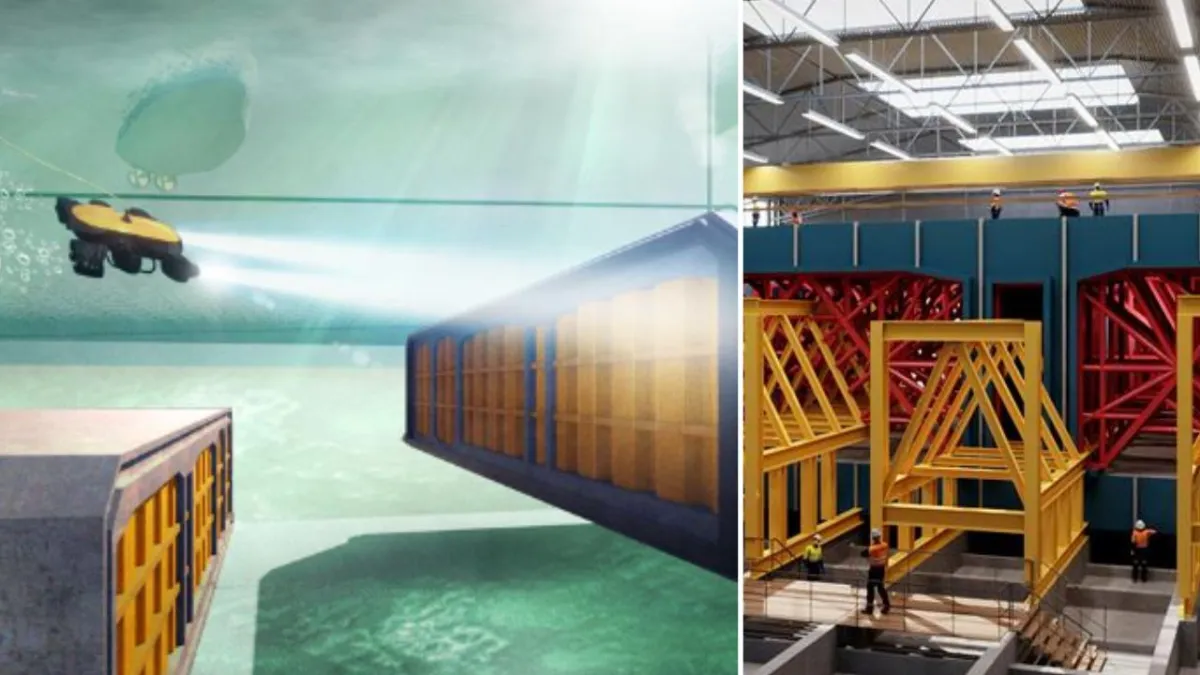

Unlike other underwater tunnels dug into the seabed, the Fehmarnbelt is built from prefabricated concrete modules, which are subsequently submerged and assembled underwater. Each module has impressive dimensions: 217 meters long, 42 meters wide and weighs 73,000 tons. These parts are manufactured on land and then transported to sea for installation.

Steel plays a crucial role in the strength and durability of the tunnel. It is estimated that an amount equivalent to the material used in 50 Eiffel Towers will be needed. Every week, 1,500 tons of steel bars 15 meters long and 32 millimeters in diameter are produced. which will be used to reinforce the concrete modules. A state-of-the-art magnetic crane and specialized robots are responsible for assembling these pieces underwater, according to data collected from the Femern website, the official one that shows the developments of this great advance.

Fehmarn Sund Baelt

Challenges faced by the project

When it comes into operation in 2029, the tunnel will dramatically reduce travel times. Currently, crossing the strait between the islands of Fehmarn (Germany) and Lolland (Denmark) by ferry takes about 45 minutes, not counting waits. With the tunnel, the car journey will be just 10 minutes. For trains, the time will be even less: only 7 minutes at a speed of 200 km/h.

This tunnel will not only connect Germany and Denmark; It will be a crucial link on the E47 route, which links Germany, Denmark and Sweden, facilitating trade and tourism in the region. In addition, the travel time between Hamburg and Copenhagen will be reduced from almost five hours to just two and a half hours.

However, it has not been without controversy. The project faced legal and environmental challenges as it passes through a protected reef zone. Organizations such as the German Association for Environmental Protection tried to stop its construction. Additionally, some local residents fear that the tunnel will significantly increase traffic in the connecting areas.

Fehmarn Sund Baelt

A challenge of epic proportions

With an estimated cost of €7 billion, the Fehmarnbelt Fixed Link is one of the most ambitious infrastructure projects in Europe. More than 3,000 people work on this project, which is expected to take eight and a half years to complete. Since 2022, when construction was given the definitive green light, significant progress has been made, such as the completion of the first module in 2023 and the construction of the permanent dock on the Danish coast. For this reason, several advanced and rigorous measures have been implemented:

- GPS technology and positioning systems: High-precision GPS systems and other positioning technologies are used to ensure that the prefabricated modules are placed in exactly the right place on the seabed.

- Modeling and simulation: Prior to construction, extensive computer modeling and simulations are performed to anticipate and troubleshoot potential problems. This includes simulations of sea conditions and the structural behavior of the tunnel.

- Constant monitoring: During construction, constant monitoring of the modules and the marine environment is carried out. Sensors and real-time monitoring equipment help detect any deviations or problems immediately.

- Rigorous Inspections and Testing: Each concrete module It undergoes rigorous inspections and testing before being placed. This ensures that they meet the necessary quality and safety standards.

- Specialized equipment: Specialized construction equipment, such as floating cranes and positioning vessels, is used to are designed to handle the specific conditions of the marine environment and to place the modules precisely.

Fehmarn Sund Baelt

(You may be interested: Inmates dug a tunnel to escape from prison in Cúcuta)

Source: https://www.noticiascaracol.com/mundo/asi-estan-construyendo-el-tunel-submarino-mas-largo-del-mundo-hay-toneladas-de-hormigon-y-acero-so35